Rolled thread or cut thread? Differences and advantages

Mechanical parts can be manufactured with different techniques. These include thread rolling and thread cutting. What type of threading should be used in which case? Which threading is used for the manufacture of CODIPRO’s lifting rings and why? In this article, we’ll have a closer look at this subject.

Cut vs. rolled thread

Machined threading (cut threads) consists of removing material. The metal is cut away in several successive steps with a considerable loss of material. The fibers of the material are thus “cut” and broken.

Manufacturing mechanical parts using the thread rolling process consists of deforming a part under the force of rotating presses. The material is thus deformed by cold forming and not cut. This particularity of thread rolling results in a better tensile strength.

At CODIPRO, the threaded bolts of the standard lifting rings are manufactured using the thread rolling process. This is a significant advantage for the products and their users.

Static tensile strength

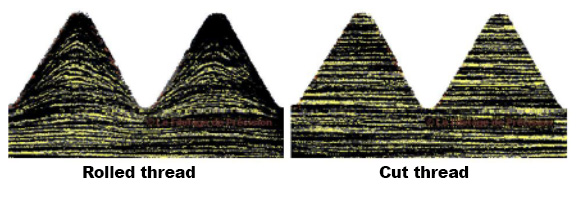

Because the metal fiber is not cut, the thread rolling process naturally increases the thread strength. The cross-sectional view below demonstrates the difference between the two techniques: rolled thread (deformed material) and cut thread (cut material).

Material hardness and fatigue strength

One of the characteristics of thread rolling is the hardening of the part. At the bottom of the thread, a zone of very high compression, the material can be deformed up to 200 percent. This greatly increases the surface hardness of the material and creates a state of compression that prevents formation of cracks and their propagation, which also results in better fatigue resistance. Concretely, the fatigue strength of cold-rolled threads can be up to 30 percent higher compared to cut threads.

Rolled vs. cut threads

The mechanical strength of a threaded element is therefore influenced by the threading process. The characteristics of a rolled thread compared to a cut thread can be summarized as follows:

- Tensile strength -> up to 10% higher

- Shear strength -> better, due to the crack propagation mode

- Fatigue strength -> up to 30% higher

The working load limits and safety coefficients of a lifting ring manufactured with a rolled thread can therefore be much higher than those of the same lifting ring with a cut thread.